In logistics and supply chain management, stretch wrap is an essential tool for securing products on pallets and ensuring they arrive safely to their destination. However, not all stretch wrap is created equal, and many businesses may not be getting the full value from their investment. If your stretch wrap isn’t performing as expected, it could be costing your business in more ways than one.

In this blog, we’ll explore the common pitfalls that businesses often encounter when purchasing stretch wrap and how you can avoid them. Plus, we’ll introduce you to our Pallet Wrap Optimisation service and Nanofilms, designed to deliver exceptional value and performance.

Common pitfalls in purchasing stretch wrap

Inconsistent Quality: One of the most frustrating issues businesses face with stretch wrap is inconsistent quality. You might start with a product that seems strong and effective, but over time, the quality degrades. This can lead to reduced load stability, increased product damage during transit, and ultimately, higher costs as you use more wrap to compensate for the decline in performance.

Widening Tolerances: As manufacturers aim to cut costs, you may find that the tolerances in your stretch wrap are widening. This means greater variability in the thickness, stretch, and overall performance of the film. These variances can lead to inconsistent wrapping, affecting the security of your loads and causing inefficiencies in your operations.

Short Length Rolls: A sneaky tactic some manufacturers use to reduce material costs, is producing rolls that are shorter than advertised. You think you’re getting a full-length roll, but you’re receiving less film than expected. This not only means you run out of wrap quicker, but it also increases your per-pallet wrapping costs.

Heavy Cores: Another way manufacturers cut material is by using heavier cores. While this might not seem important, it adds unnecessary weight and reduces the amount of usable film per roll. This tactic can be misleading and cost your business more in the long run.

Lower Grade Polymers: To reduce costs, some stretch wrap manufacturers use lower-grade polymers. These inferior materials compromise the effectiveness of the wrap, leading to poor stretch performance, reduced load containment, and a higher risk of product damage during transport.

False Sustainability Claims: In today’s eco-conscious market, many manufacturers make bold sustainability claims. However, not all these claims are backed by real data. Some companies use vague definitions or operate in less regulated regions, making it difficult to verify the environmental benefits of their products. As a result, you may be using a product that isn’t as sustainable as you were led to believe.

Lengthy Lead Times & Shipping Price Fluctuations: Finally, unpredictable lead times and fluctuating shipping prices can disrupt your operations. If your supplier can’t deliver stretch wrap consistently and at a stable price, it can lead to delays, increased costs, and challenges in maintaining inventory levels.

The Solution: Pallet Wrap Optimisation and Nano Films from Zeus

At Zeus, we understand the importance of getting real value from your stretch wrap. That’s why we’ve developed a comprehensive pallet wrap optimisation service, along with our advanced Nano stretch films, to help businesses like yours overcome these common pitfalls.

Pallet Wrap Optimisation

Our pallet wrap optimisation service is designed to ensure that your stretch wrap system is operating at peak efficiency. We start by conducting a thorough analysis of your current wrapping processes, identifying areas where improvements can be made. Our experts then recommend adjustments to your machinery, film, and processes to achieve optimal performance. The result? Significant cost savings reduced plastic waste, and enhanced load stability. Our audits are completely free of charge and unbiased. If you’re already operating at peak efficiency, we will tell you so! There is never any pressure to change supplier after an audit, we leave you with the results to make a choice that works for you.

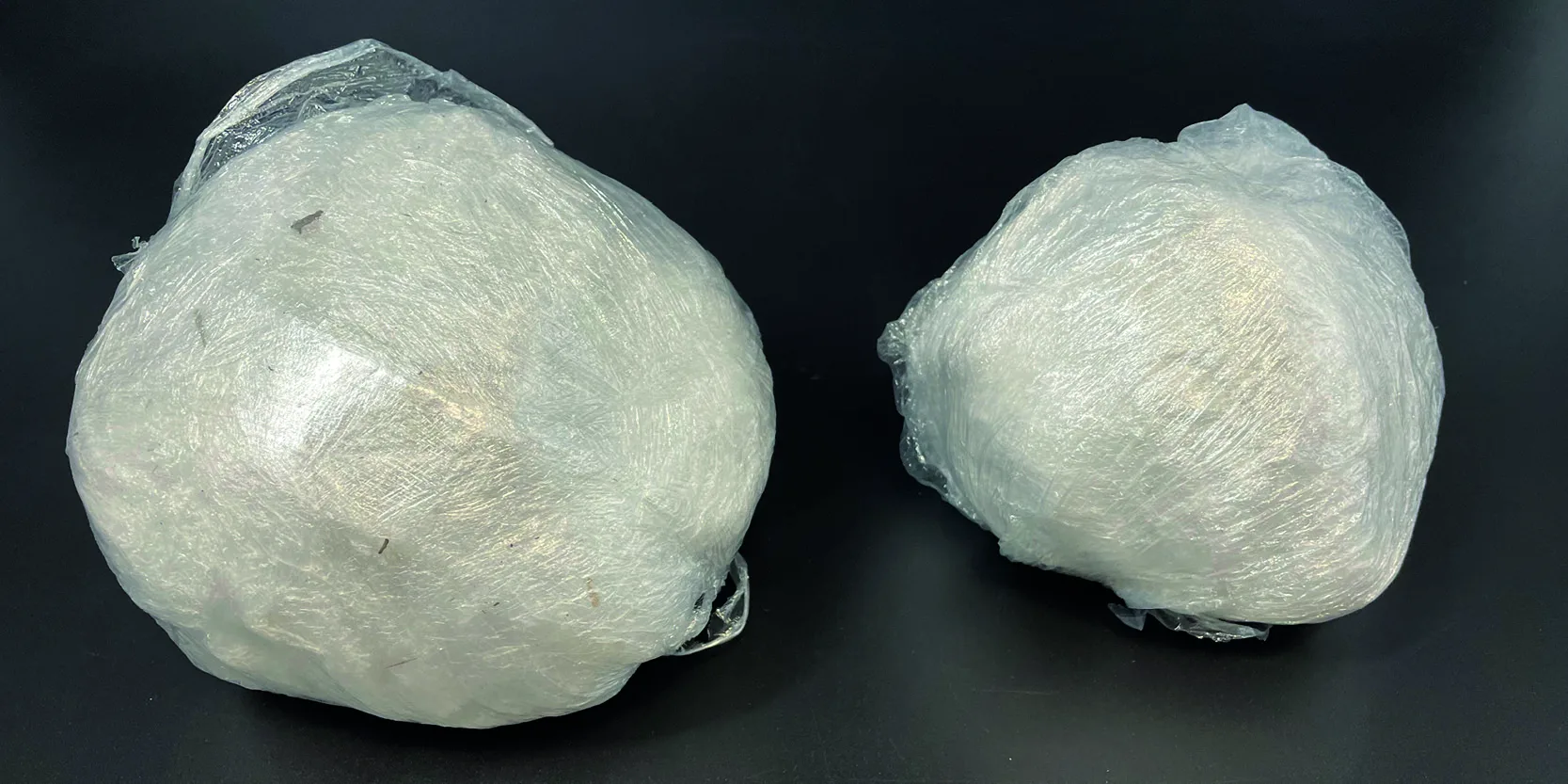

Introducing Our Nano Films

Our Nano films represent the latest in stretch wrap technology. Manufactured using advanced nanotechnology, these films offer superior strength, stretchability, and load containment. With a stretch capacity of up to 260%, our Nano films allow you to wrap more pallets with less film, reducing your material usage and costs. Plus, they provide excellent puncture and tear resistance, ensuring that your products are securely wrapped.

If you’re unsure whether you’re getting the best value from your stretch wrap, it might be time for a change. By avoiding the common pitfalls and investing in pallet wrap optimisation and high-performance Nano films from Zeus Packaging, you can enhance your operations, reduce costs, and contribute to a more sustainable future.

Ready to optimise your pallet wrapping process and start saving with a company that leads with honesty and integrity? Contact us today to learn more about our audits and how our Nano films can revolutionise your packaging operations.

Contact Us: sales@zeuspackaging.com