Our online platform is linked to the sensors installed on your wrapping machine, where all parameters and alerts are monitored.

The all-in-one measuring solution

for pallet wrapping

Improves performance, reducing

time, costs and emissions

Our comprehensive solution gives you complete control of your pallet wrapping process

What is Apollo for?

Provides the true costs of your pallet wrap process

Track data analysis in real time 24 hrs 7 days

Gives complete transparency and eliminates inefficiencies

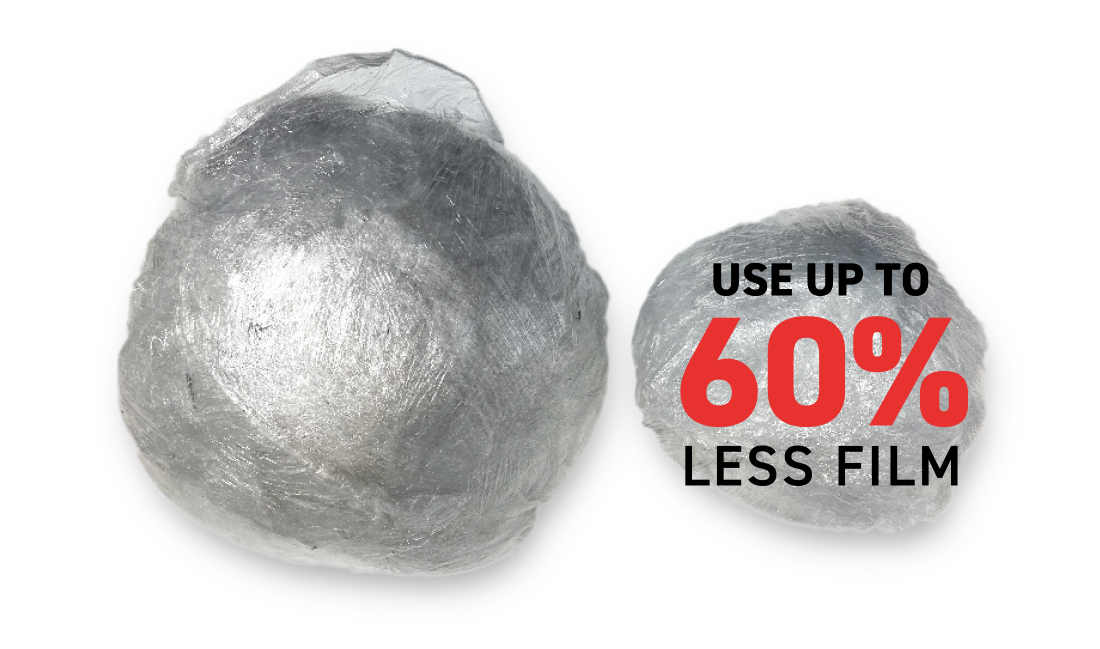

Uses up to 60% less film, and generates less waste

Reduces CO2 emissions

Delivers a complete optimised pallet wrap process

Watch this explanatory video

What does Apollo measure?

Net weight of film used per pallet

Actual pre-stretching per pallet

Actual meters of film used per pallet

Real pallets wrapped by coil

Number of pallets produced per period

Cost in £/€ per wrapped pallet

Perform a free optimization study!Perform a free optimization study!

Use Apollo anywhere

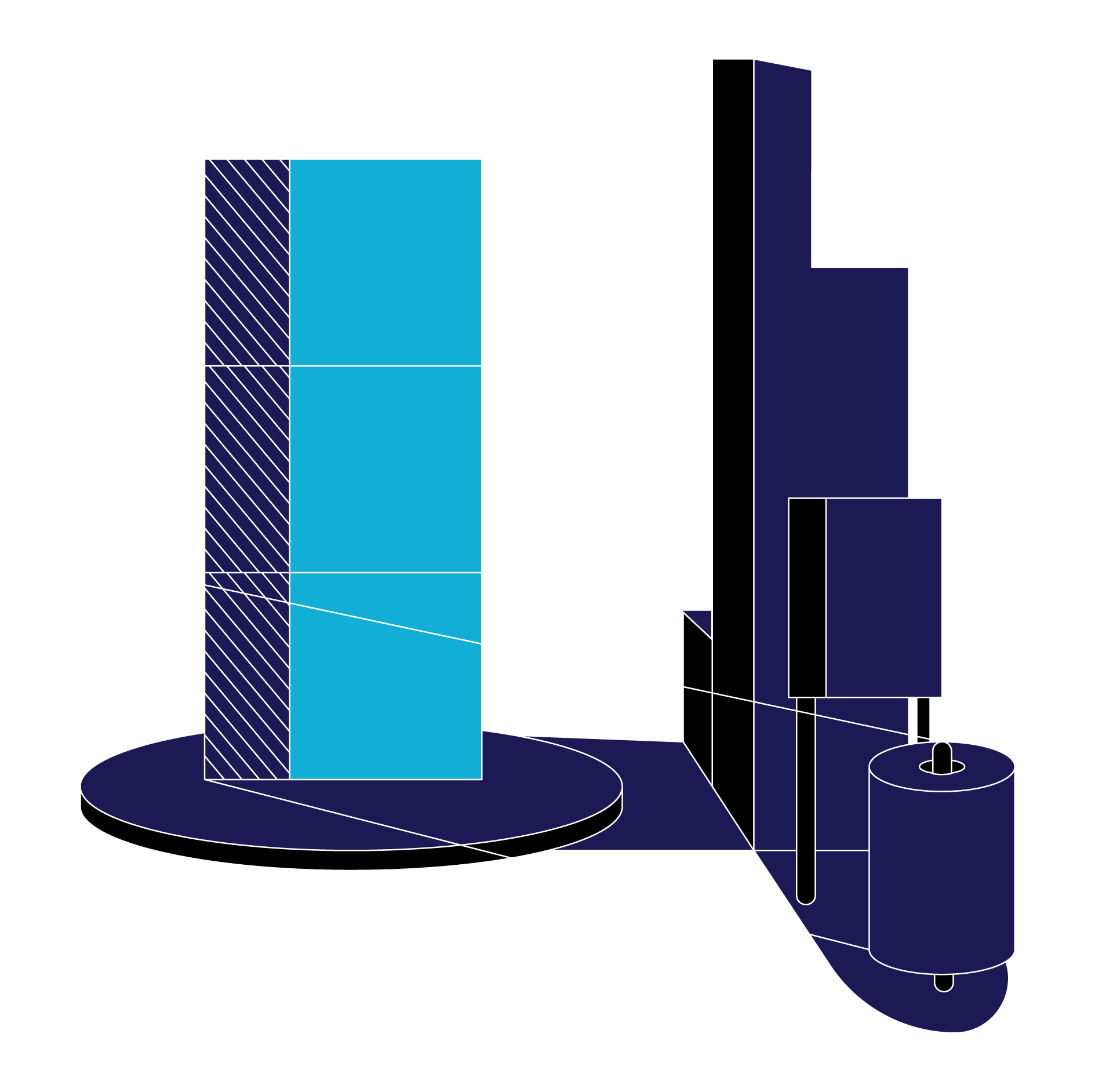

The Apollo Pallet Wrapping Monitoring System consists of three key components: machinery, software and high-performance film

- the only cost is the film you use!

Machinery

Software

Film

Film with high performance

Our range of high performance films are designed to give you maximum strength and stretch at low thicknesses.

Wrapping machines

We install sensors to monitor the key metrics of your business. We adapt or update your machines as necessary.

Ongoing maintenance service is included.

Transparency is the result of real-time data

We are all responsible for helping our planet!

The APOLLO system aims to

help you use less plastic.

This will reduce your emissions and

increase your sustainability credentials.

Need more information?

Fill out the form on the right or contact us at:

apollosales@zeuspackaging.com