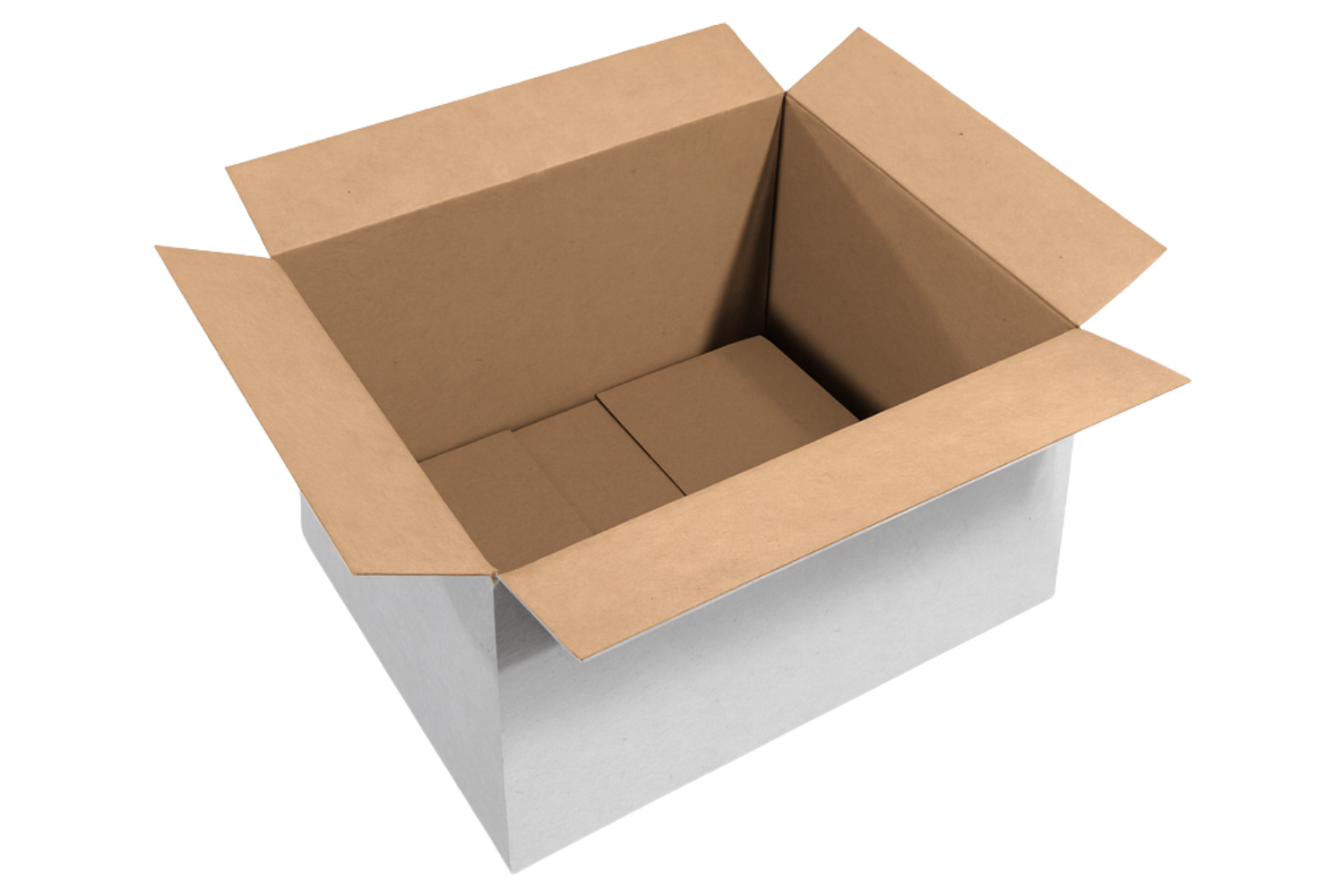

Carton erector machines are automated systems that form flat-packed cardboard boxes into open cartons, sealing the bottom flaps with tape or glue. Designed to improve packing line efficiency, they reduce manual labor, speed up box preparation, and ensure consistent box quality—ideal for high-volume packaging operations in industries like e-commerce, food, and logistics.

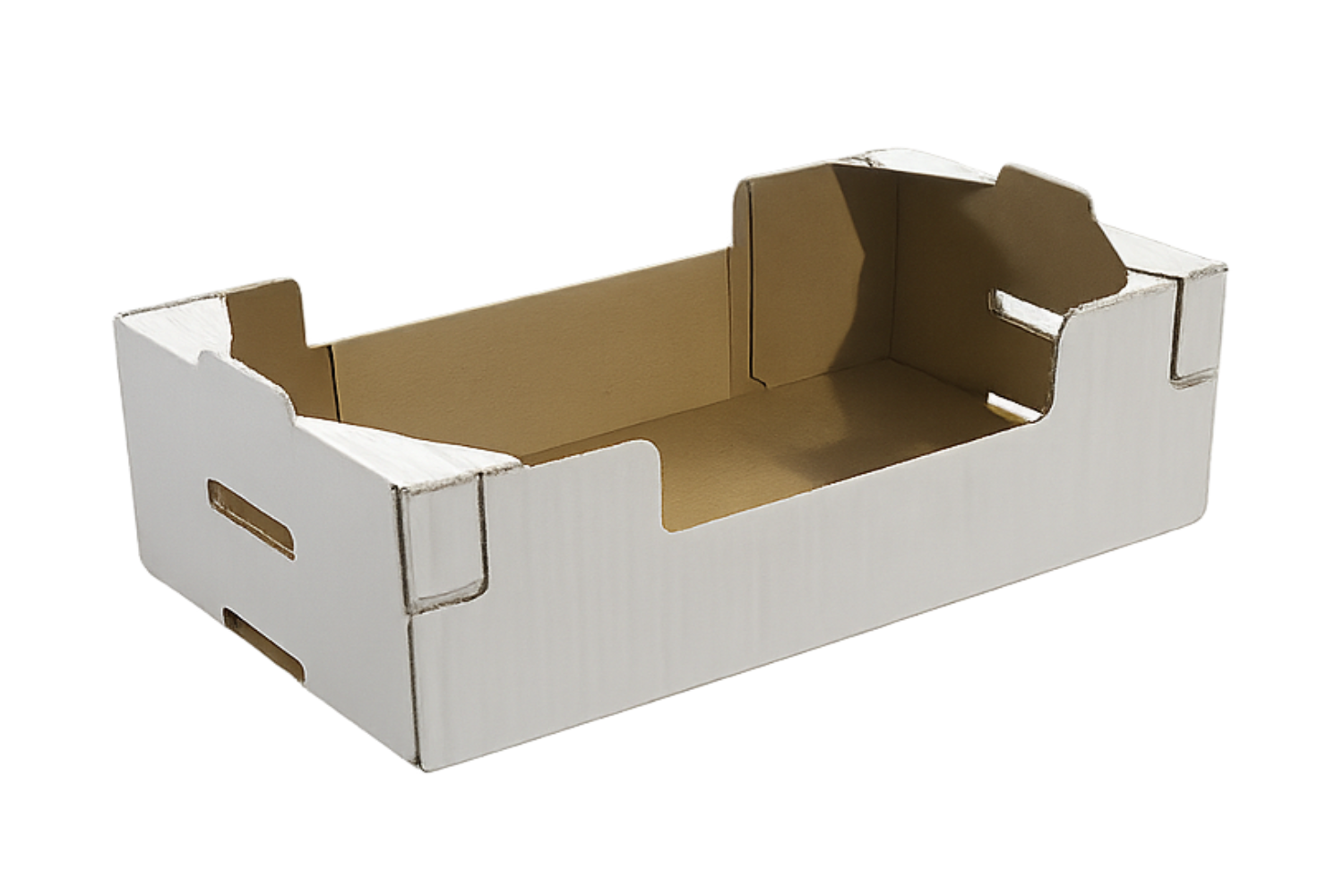

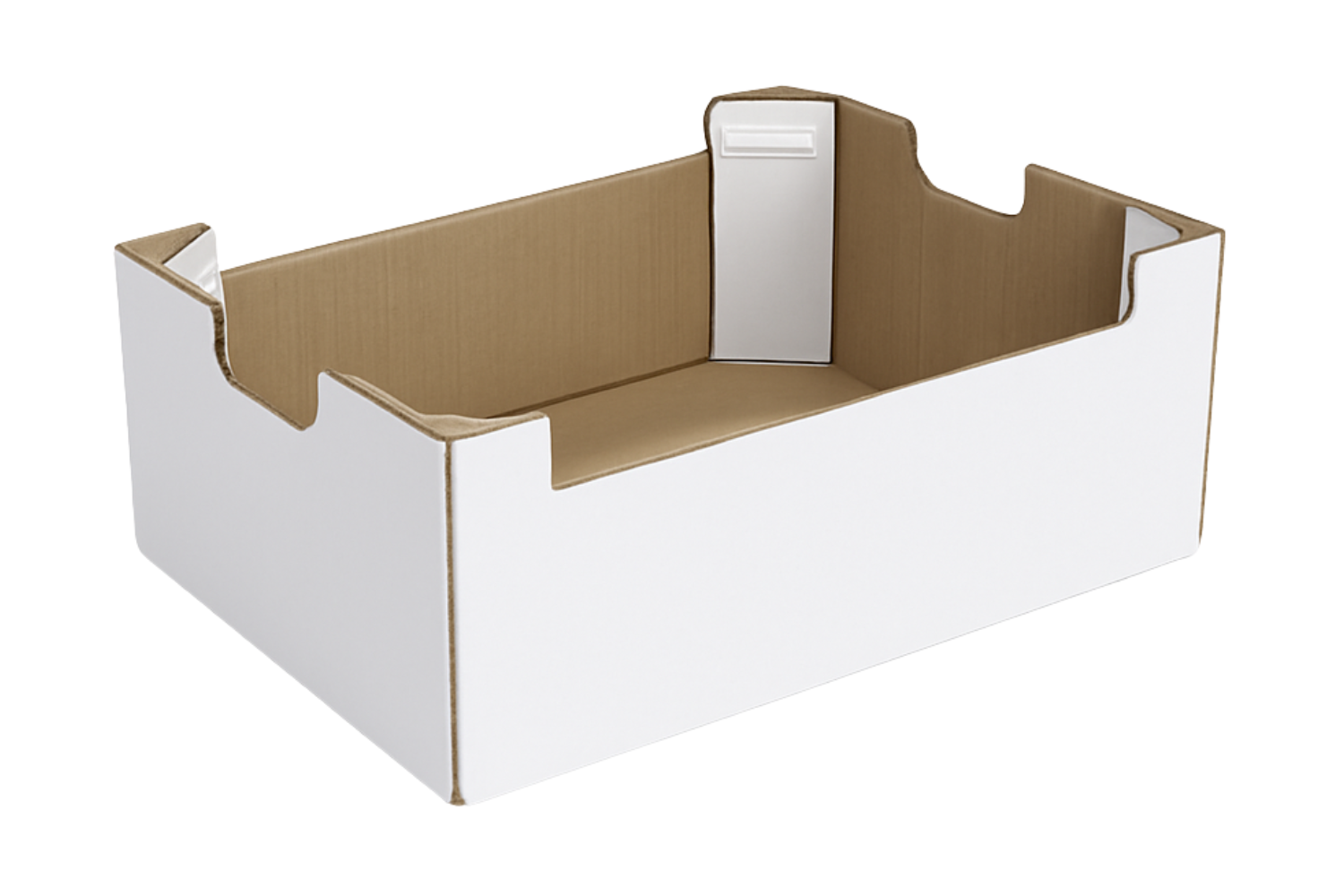

Tray erectors for corrugated cardboard are automated machines designed to form flat cardboard blanks into sturdy trays ready for packing. These systems streamline packaging lines by quickly folding, gluing, and locking trays with precision, ensuring consistent quality and reducing manual labor. Ideal for industries such as food, electronics, and consumer goods, tray erectors improve efficiency, maintain product protection, and support high-speed production environments.

for carton punnets

Automatic tray formers for carton punnets are high-speed machines that fold and glue flat cardboard blanks into sturdy trays. Designed for quick changeovers and efficient production, they ensure consistent, durable packaging ideal for fresh produce, confectionery, and consumer goods. Compact and easy to integrate, these machines boost packaging efficiency and reduce labor.

for american boxes

Automatic case formers for American-style boxes (Regular Slotted Containers, RSC) are high-speed machines designed to automatically fold and seal flat corrugated blanks into sturdy, square-bottomed boxes. They improve packaging efficiency by reducing manual labor, ensuring consistent quality, and enhancing ergonomics. Ideal for food & beverage, e-commerce, and logistics, they support high-volume operations with quick changeovers and reliable performance.

Different types of trays, punnets and boxes:

Tray with top flap

Tray with short and

long side doublewall

Citrus tray

Open top tray

with reinforced corner post

Display tray (SRP)

American box (RSC)

Punnet

Plastic crate with

foldable side